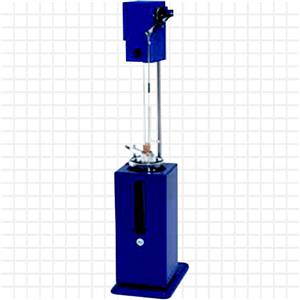

Freezing Point Apparatus

Test Method

The Freezing Point of an Aviation Fuel is the Lowest Temperature at which the fuel remains free of Solid Hydrocarbon Crystals that can restrict the flow of fuel. The Temperature of the Fuel in the Aircraft Tank normally falls during flight depending upon Aircraft Speed, Altitude, and flight duration. The freezing point of the fuel must be lower than the minimum operational tank temperature. The test determines the temperature below which solid hydrocarbon crystals form in Aviation fuels. The sample is cooled with continuous stirring in a dewar-type sample tube until crystals appear.

Standard:-Conforms To ASTM D1177 , ASTM D2386 Specifications

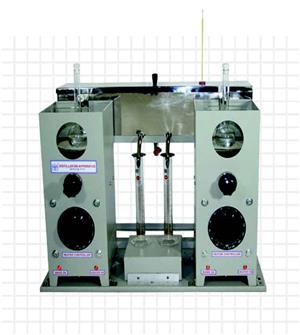

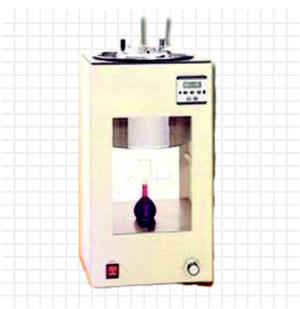

Manual Freezing Model (Hi-Tech 23A)

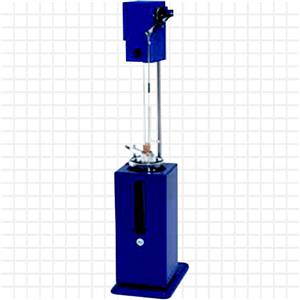

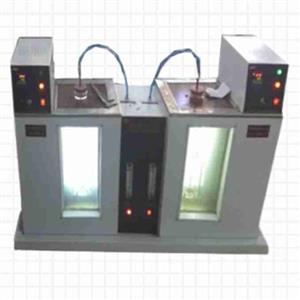

Apparatus

Consist of one wooden insulated assembly , one Dewar Flask, Stirrer for above, Illumination Facility, Freezing Point Tube and Front Window for Observation along with Thermometer (with Calibration Certificate) for temperature observation.

Maximum Temperature

100°F (-73°C)

Electrical Connection

230V 50/60Hz, Single Phase, 4.5A